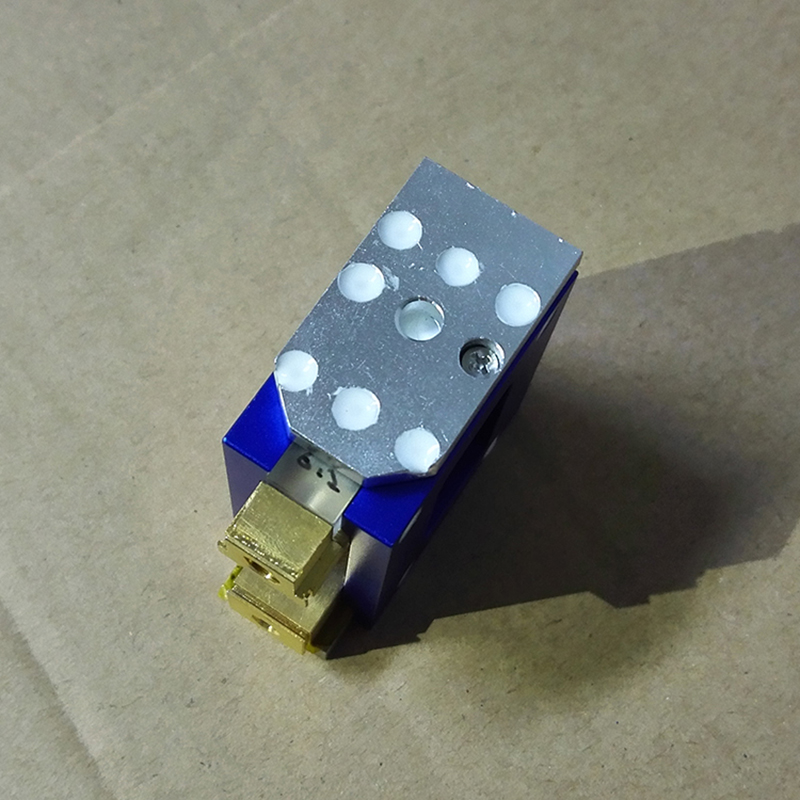

Alma lasers Soprano Platinium Diode Block Repairing Service

Laser diode Specifications:

| Model No. | VS-MI-Alma-12-100-1 |

| Application | Repair And Replacement Alma lasers soprano XL,XLi, Soprano ICE |

| Operation Mode | CW |

| Power per submounts | 100W |

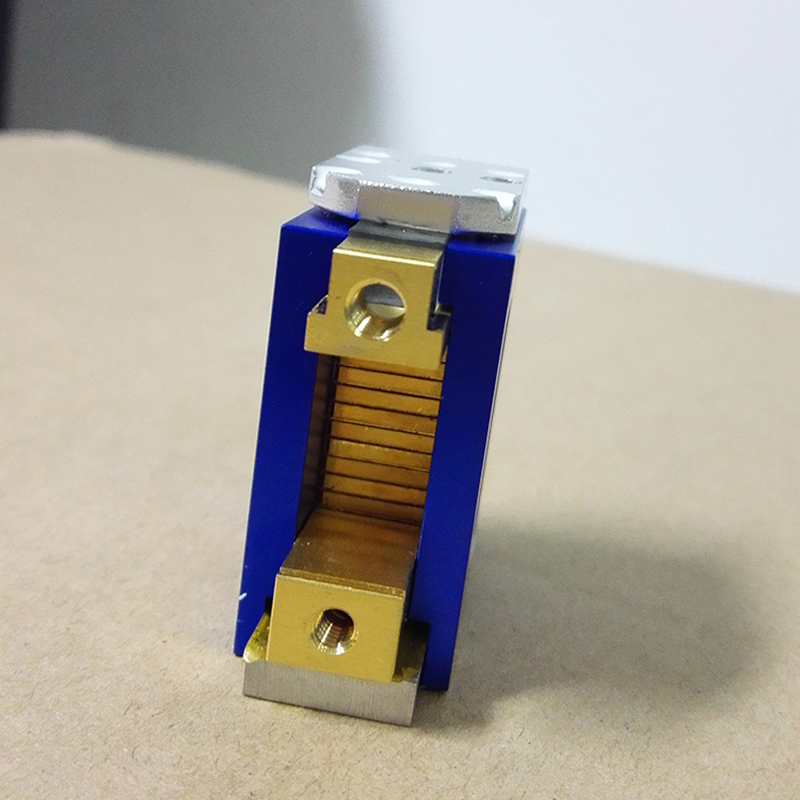

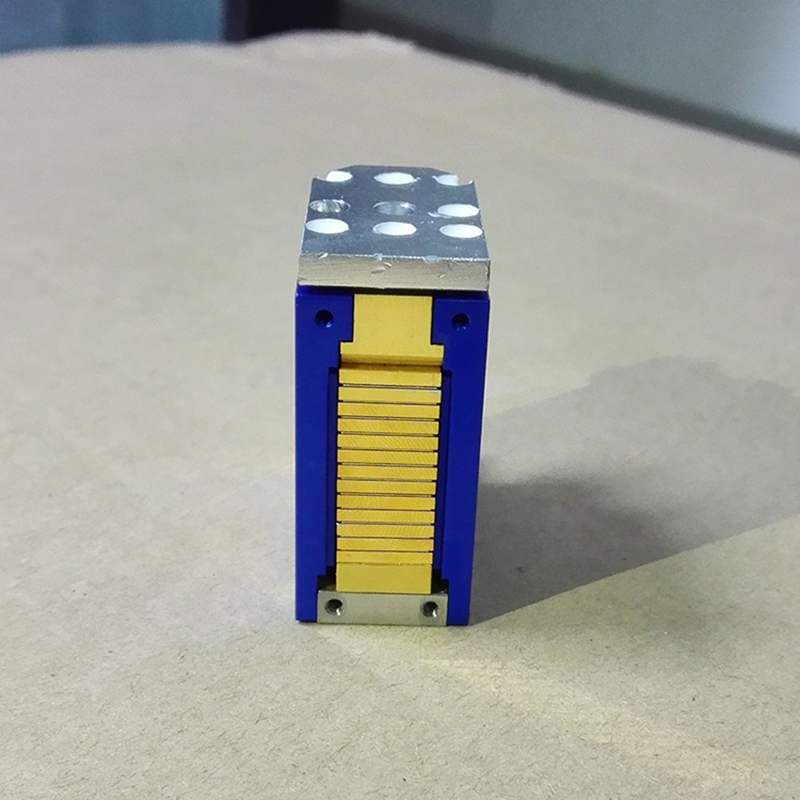

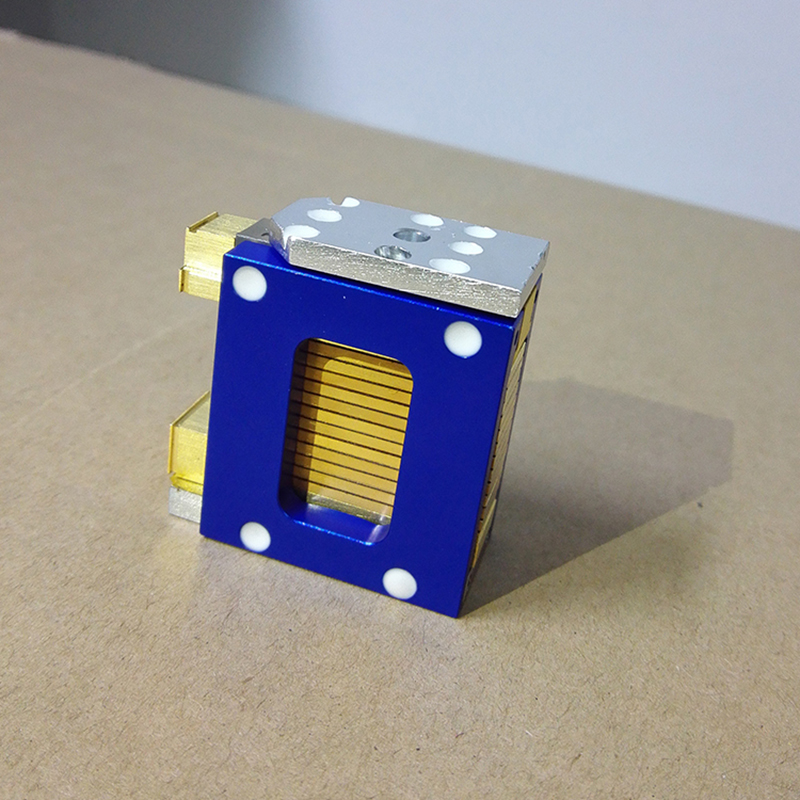

| Number of submounts in one stack | 12 bars |

| Central wavelength at 25℃ | 808 ± 5nm also we can make 755nm or 1064nm and 3D wave combination also available |

| Typical Operation current | 50A |

| Maximum Operating current | 90A |

| Typical Threshold current | 8A |

| Maximum Operating Voltage | <24 V |

| Fast Axis Divergence (FWHM) | 39º |

| Slow Axis Divergence (FWHM) | 8º |

| Operation Condition | non-condensing atmosphere, cleaning room |

| Expected lifetime | 10- 20 millions shots |

| Typical pitch per bar | 2mm |

| Cooling requirement | |

| Flow rate | >3.5L/min |

| Water Temperature | 27+-3°C |

| Water Quality | pure water |

| cooling system | Do not use any material that combination with copper would form galvanic elements |

Laser diode repair process:

With email or whatsapp , you can send us picture or video to show me the problem. When confirm the repair service, the process as:

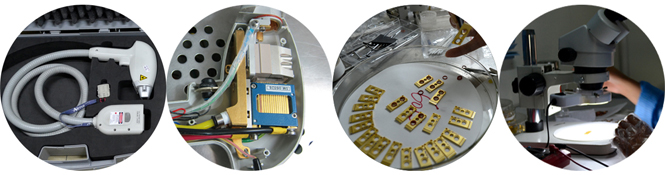

A.Deliver the problem laser diode handle or 808nm laser diode stack

B.Our technician check the laser, and we will offer you quotation for free service

C.You can confirm to repair the laser handle or laser diode head

D.We will change the damage laser bar to new bars

E.We will send you test report and video and also picture for new laser head or laser handle after refurbishment

F.We will pack the good laser head or laser handle and then deliver to you

Repair & Refurbishment Services Process:

1.Provide the service information you need.

Yod need send us a alma laser stack or product information picture to us.(Email,whatsapp,skype) as above picture shows.We confirm and customize the repair plan for you.

After that, Firstly you need send the laser diode head to us, if can not send old diode,need send to us structure design of the diode and dimension details stack. We will repair the old diode or design a new stack to replace the old one.We should confirm your handle is A, B ,C or D, E, F, G ,H, I ,J options as the mentioned before.

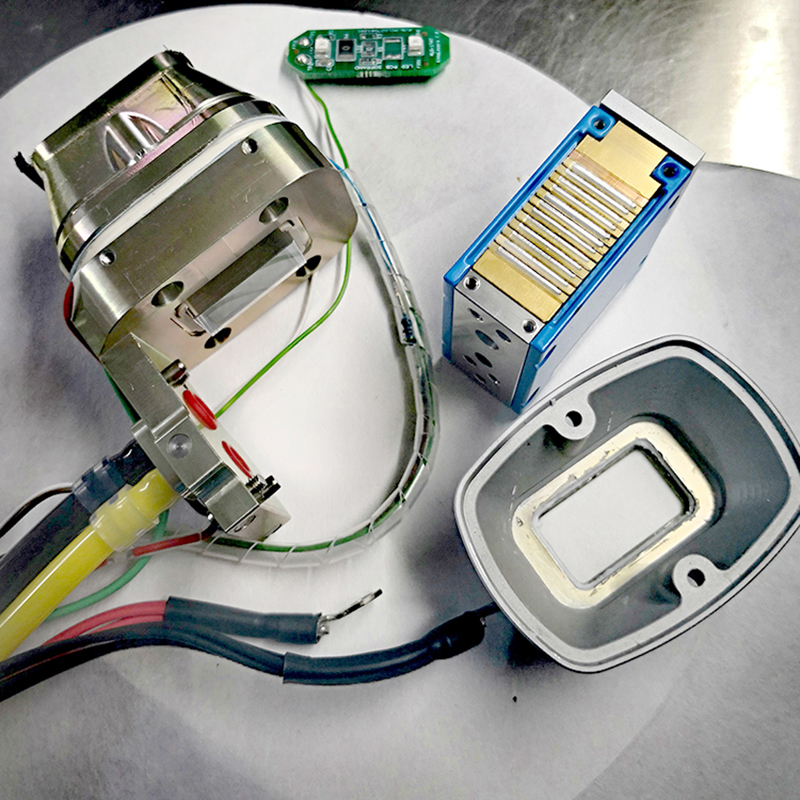

2.we disassemble the diode stack, and test the old laser stack. For the micro channel laser stack, Such as Alma laser, Lightsheer, Syneron. We will test each laser plate one by one to confirm whether there are any one bars still can work. If there have some good bars, the repairing charge will lower. For macro laser stack like most product made in China, we will test whole laser stack together

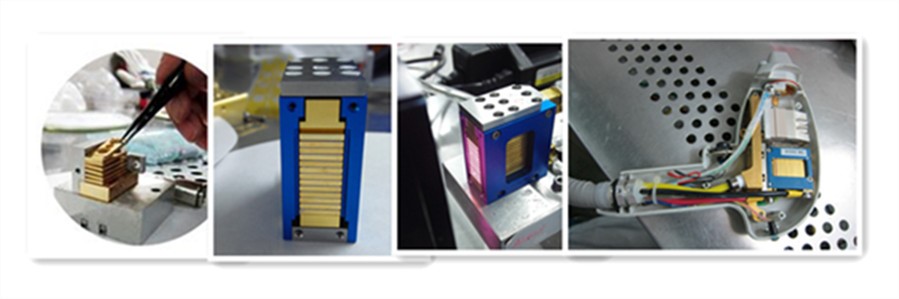

3.We will mount diode bar to heat sink and assemble diode stack to old or structure in our cleaning lab Our bars and micro channel cooler are import from Germany manufacture. We strictly manage mounting, assembling and testing step during laser stack producing. Every stack will be fully tested and had 8 hours burning test.

4.The Fourth step:

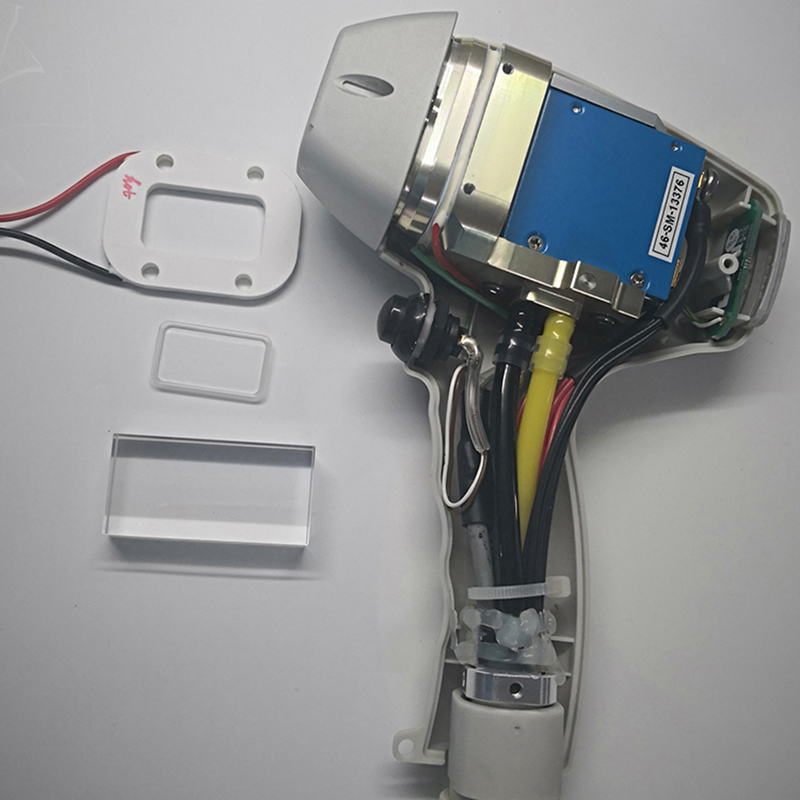

Our experienced technician will reassemble the handle piece. Which include:

- Install the new laser stack into the handle piece.

- Clean lens and check the TEC and other parts inside the handle piece

- Test the power output of whole handle piece.

- Clean the cover shell of handle piece and package it.

5.We send the finished good diode laser stack or hand piece to your address

Any more question please kindly add my whatsapp 0086-13522789042